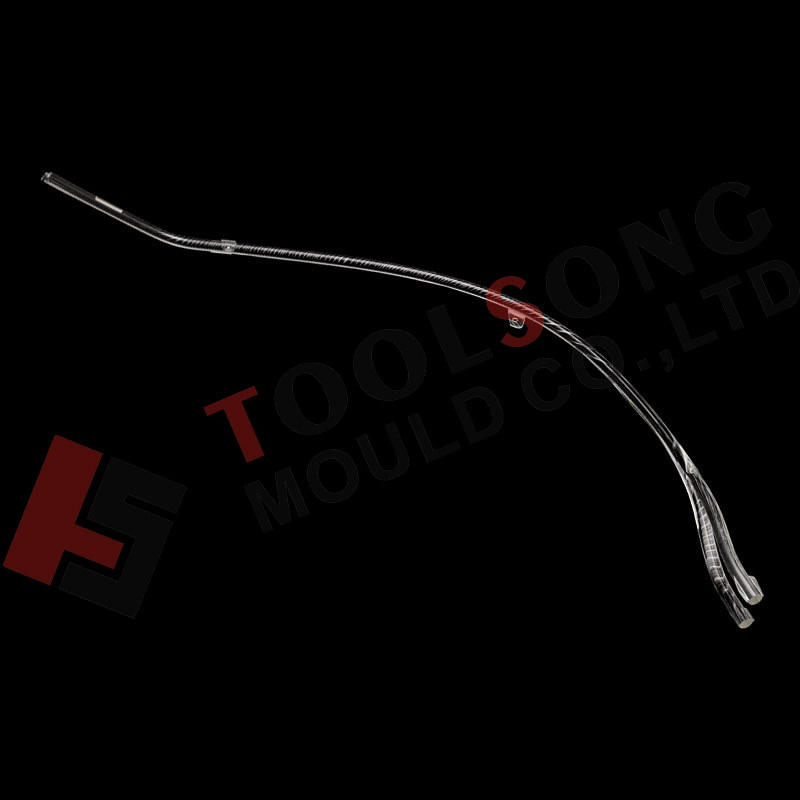

The light pipe can be longer, or even up to 1,300mm in length. We can ensure uniform light distribution through excellent mold design and precision mold machining.

The optical serrations are stitched for better machining and adjustment. The processing of light guide requires smooth machining paths, balanced cutting force, uniform allowance, etc.

We build molds for different sizes and shapes of light guides for headlamps and taillamps, no matter simple cylindrical or complex shapes.

For LED powered light guide mould, the optical surface is manufactured by high-speed CNC with the speed of 60,000RPM.

To achieve uniform homogenization of PC or PMMA light guides, we cross-check the photometric design in the design stage, and use cutter R0.05 in mold machining.