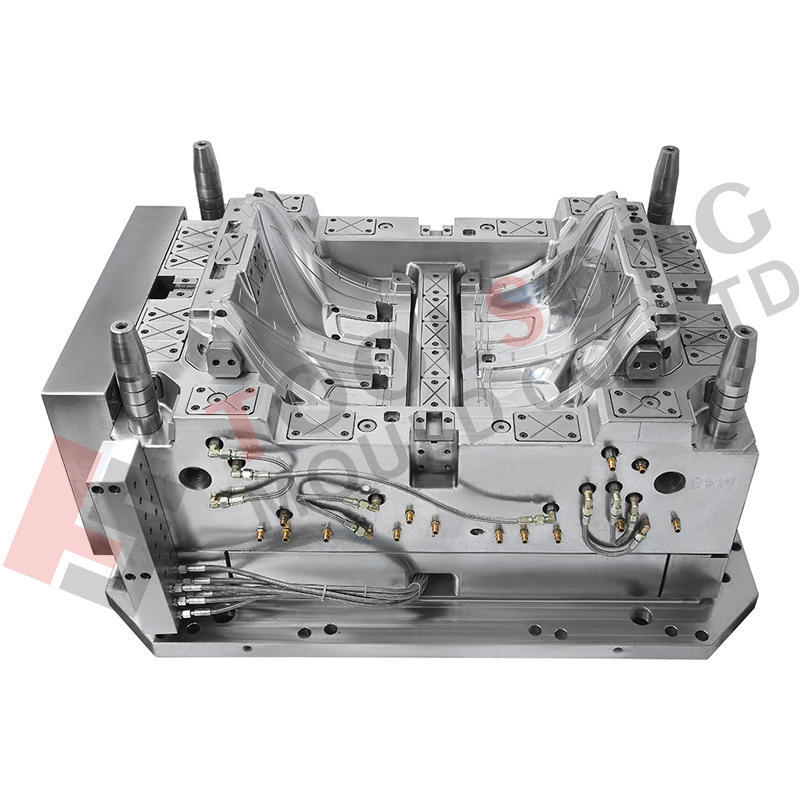

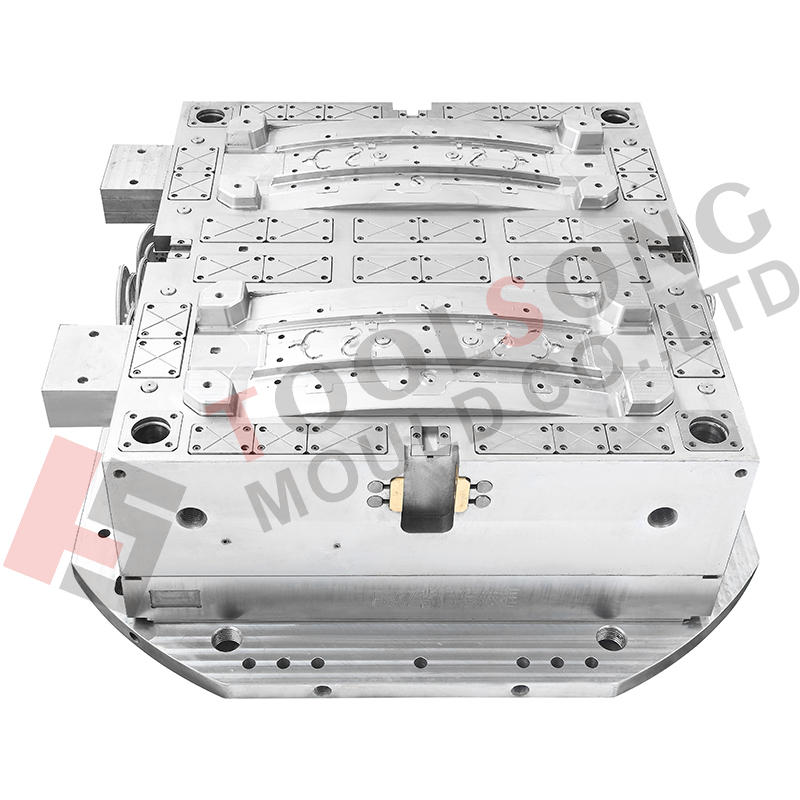

In 2K mold design and development, we need a balanced configuration injection system, hot runner system, cooling system, etc. Two cores and two cavities should be perfectly fitting.

High-precision finishing in a single process on the P/L surface and part surface is essential. It enhances the machining efficiency and accuracy, reduces the time of polishing and clamping, and guarantees the part quality.

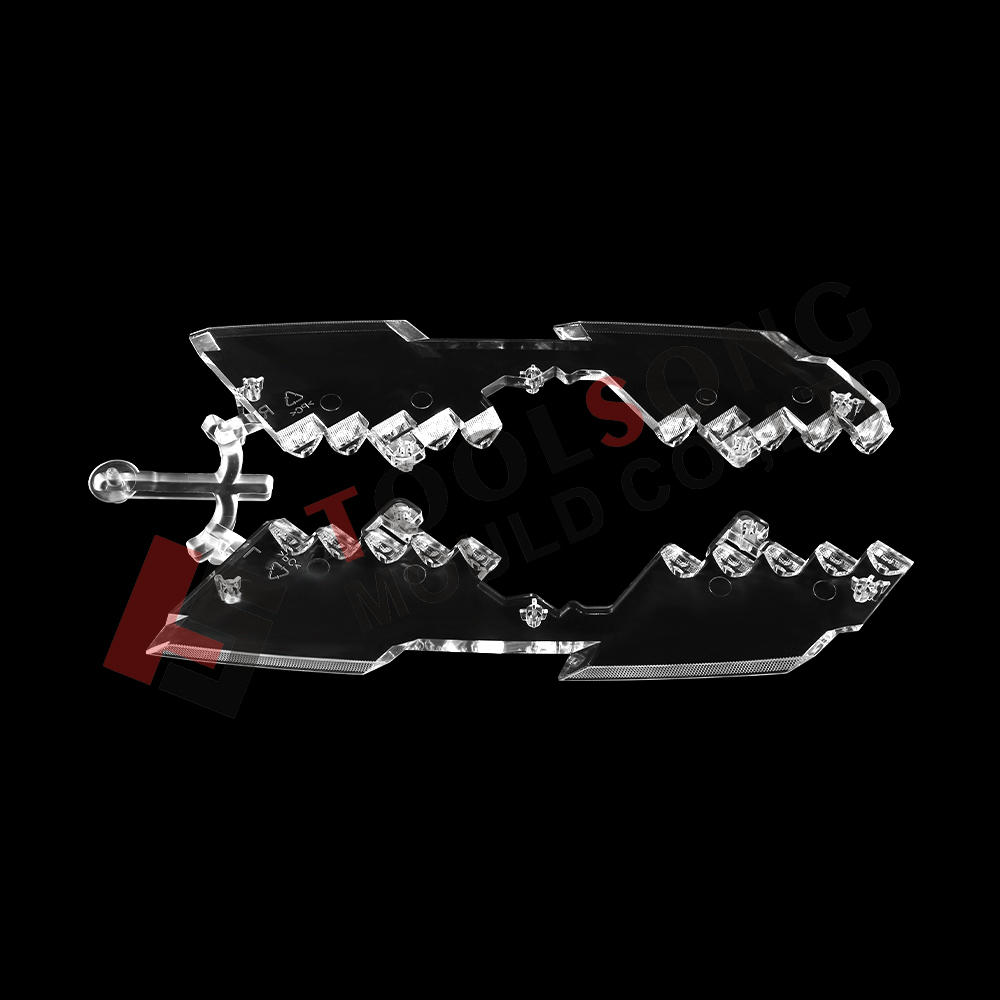

High glossy PC thick-wall light guide, using HRS hot runner, 1.2343ESR steel for core and cavity. Mold weight 2,280kgs.

We make quality light guide molds for OEM and Tier 1, and provide in-house light guide molding service. The part surface is without sink marks and flow marks.

PC transparent light guide mold with HRS hot runner system, mold cavities LH+RH. Moulded light guide weight 375g, Mold dimension 1320*760*719mm, mold weight 4,400kg.

Rich experience in making thick light guide molds with adequate cooling channels through both sides. No bubbles, no sink marks, and no other moulding defects. 470T moulding machine.